Several weeks ago, I found a good-quality pressure-treated 2x12 at Home Depot. A contractor friend cut it to the required length and then I let it season in the garage. Yesterday I used a vibration sander to remove any rough edges and smooth all the corners. I cut four lengths of cedar 1x2 using a mitre board to give the ends 45-degree angles and then fastened them 3 inches from each end on both sides using 2-inch stainless steel screws. They will act as friction reducers to save wear and tear on the heavy-duty non-skid tape and floating lines that will be attached after the wood is sealed with several coats of Cetol. But the sealing will need to wait until the temperature in the garage gets above 50 degrees, at least 20 degrees above where it is now.

Next, I drilled 5/8" holes 1-1/2'' from each corner for the floating lines, which are 4-foot lengths of Samson 3/8" Floatine multi-filament polypropylene. As a final touch, I wood-burned our boat's initials, "WJ", on one side at each end so there's no question about whose boat the gangplank goes with.

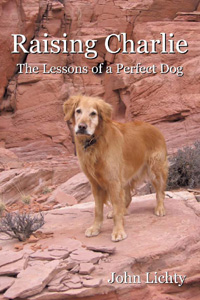

Raising Charlie: The Lessons of a Perfect Dog

Raising Charlie: The Lessons of a Perfect Dog

No comments:

Post a Comment